■ Description:

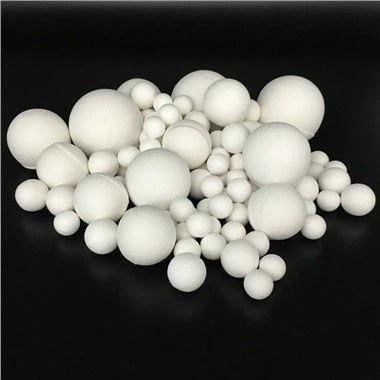

Alumina ceramic ball refers to the ball stone which is made of bauxite, roller powder, industrial aluminum oxide powder, high-temperature calcined alpha aluminum oxide powder and other materials through batching, grinding, pulverizing (pulping, mud making), molding, drying, firing and other processes, and is widely used as grinding medium.

■ Specific:

Alumina ceramic ball is an important engineering ceramic, which is a high-tech product. Due to the characteristics of Taishi's hardness, moderate density, wear resistance, corrosion resistance and low price, as well as the problems caused by metal impurities in metal balls, alumina ceramic ball is widely used in grinding and processing of raw materials in white cement, minerals, ceramics, electronic materials, magnetic materials, coatings, paints and other industries, and is a high-quality grinding medium

Item |

95% alumina balls |

92% alumina balls |

75% alumina balls |

68% alumina balls |

Al2O3 content |

≥95% |

≥92% |

≥75% |

≥67% |

Fe2O3 content |

≤0.01% |

≤0.01% |

≤0.14% |

≤0.5% |

Density |

≥3.65g/cm3 |

≥3.65g/cm3 |

≥3.18g/cm3 |

≥2.98g/cm3 |

Abrasion |

≤0.01% |

≤0.01% |

≤0.14% |

≤0.03% |

Hardness |

9 |

9 |

8 |

8 |

Available Size |

0.5-70mm |

0.5-70mm |

30-70mm / customized |

30-70mm / customized |

■ Features of alumina grinding ball:

1. The main component of the alumina ball is high-quality alumina, which has high purity, high strength, high hardness, high whiteness, and low wear, and has little impact on the quality of the grinding materials.

2. The product is formed by rolling and isostatic pressing, which has a large proportion. It can greatly improve the grinding efficiency, reduce the grinding time, and effectively increase the effective volume of the ball mill, thus increasing the amount of grinding materials.

3. The product has low wear and can greatly extend the service life of the grinding body.

4. This product has the characteristics of high temperature resistance, acid and alkali resistance and corrosion resistance.

5. We have developed a special dry grinding ball with good toughness and low wear, which has solved the problem of raw material pollution caused by grinding media commonly found in the powder industry.

■ Product application

1. Alumina grinding balls are mainly used for finishing and deep processing of thick and hard materials of different types of ceramics, enamel, glass and chemical plants. It is the grinding medium of ball mill, tank mill, vibration mill and other fine crushing equipment, and its crushing and grinding efficiency and wear resistance are greatly superior to ordinary ball stones or natural pebbles.

2. Grinding and dispersion of non-metallic mineral product powder (such as zirconium silicate, kaolin, heavy calcium carbonate, etc.) and materials in coating, paint and other industries, as well as polishing of metal parts, are applicable to all types of grinding and polishing equipment.

3. It shall be filled in the rubber during pouring to increase the wear resistance coefficient.

4. High temperature resistance, can be used as ball under pusher kiln.

5. High strength and hardness can be used for polishing.

http://www.zbshell.com/

By certification

By certification